Coca-Cola

In recent years, the domestic beverage market has maintained a growth trend, and competition among various beverage brands has also intensified. Strengthening their brand recognition and improving quality are important factors for winning the market. In the key links of beverage production, improving the technical level, equipment performance and quality can increase the market competitiveness of beverage companies.

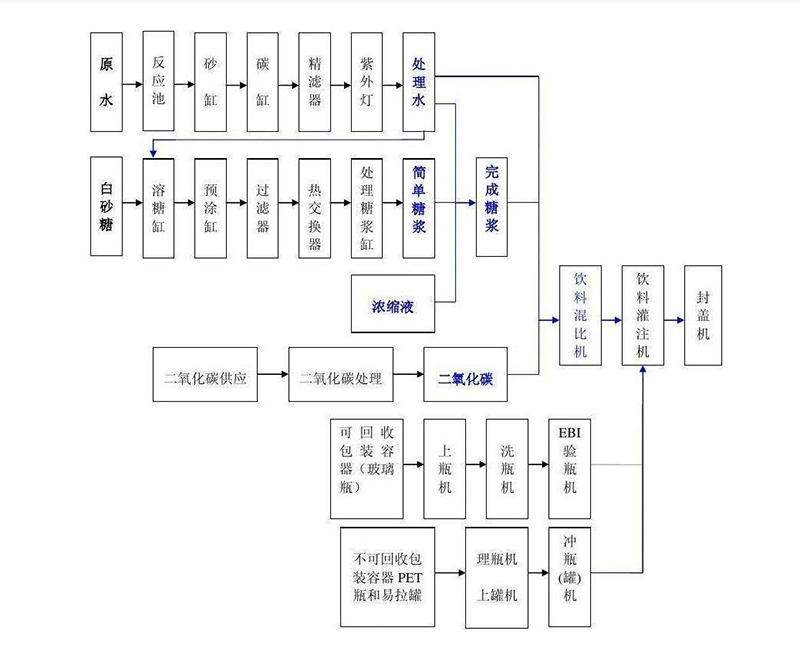

Kaydeli chiller equipment is a refrigeration equipment that provides circulating cooling water according to the customer's low-temperature and normal-temperature process requirements. It is widely used in the beverage industry to provide cooling and cooling for beverage production equipment, and to achieve the efficiency of raw pulp preparation and beverage canning Cool down. In the carbonated beverage industry, Coca-Cola and Pepsi are giants of international carbonated beverage companies. Domestic carbonated beverages also include brands such as Jianlibao, Arctic Ocean, and Laoshan Coke. Kaideli chiller is often used in finished product water treatment, syrup blending, carbonation and cooling of canned equipment in carbonated beverage production. Its professional technology and after-sales guarantee have been praised by domestic and foreign carbonated beverage companies many times.

The Coca-Cola Taikoo Huizhou factory is the 35th domestic production base of the multinational company Coca-Cola, equipped with four production lines with international advanced levels. In one of the syrup conditioning, carbonation equipment and canning production links, Kadely provides customers with an overall cooling system solution. After 6 years of operation, the whole system is still very stable, providing a solid guarantee for customers to produce efficient and stable production.

After the project was launched, Kaydeli engineers and technicians arrived at the site to fully understand the production needs and process characteristics, and communicated and communicated with the other party's technicians in detail to determine the project's demand for cold water systems.

1. The product water of the cooling source water production line is in the range of 1-3 degrees;

2. Provide proper amount and temperature of cooling circulating water for sugar dissolving system operation;

3. Provide -2 degree low temperature water to the beverage mixing machine of the carbon dioxide production line;

4. Provide -2 degree low-temperature chilled water for the beverage filling machine in one filling;

5. Fully automatic control of the chiller, reducing staffing;

6. Automatically run alternately with the load size in different seasons throughout the year to achieve the specified energy saving goal;

Based on customer needs, Kaydeli engineers and technicians have combined more than 10 years of valuable experience in the beverage industry to customize and use safe and reliable water-cooled screw chillers for customers, and provide cooling system design solutions that meet customer production needs and process characteristics.

This system adopts double-circulation refrigeration system design, equipped with 3 customized low-temperature water-cooled screw chillers (-5 degrees), 1 plate heat exchanger, 1 cooling water tower, 2 heat preservation water tanks and other refrigeration equipment.

In the sugar dissolving operation, the plate heat exchanger converts the high-temperature and normal-temperature water to ensure that the beverage pump outputs the material with the appropriate temperature; the -2 degree low-temperature chilled water is generated by the refrigeration of the screw chiller unit, the cooling gas mixing machine and the beverage filling machine ; In the double-circulation chilled water system, a 50-cubic and an 80-cubic insulated water tank are designed to realize the storage cycle of two kinds of temperature chilled water. The production water is separated from the chiller operation, and the equipment system runs more stable and energy-saving; The machine system is designed to be fully automated. The system and the operating load are automatically matched. In different seasons, automatic alternate operation is achieved, and the staffing is minimized to achieve unattended operation.

During the cooperation with the Coca-Cola Taikoo Huizhou factory, the operation of Kaydeliwater chillers was very stable. Judging from the comparison with the refrigeration systems of its peers, the operating cost was reduced by 28% and the efficiency was increased by more than 15%. Greatly save energy and labor costs.

The pursuit of beverage functions and quality by market consumers has led to the continuous improvement of the beverage industry market. Under the fierce competitive environment, beverage companies maintain advanced equipment and reduce costs, which is essential for their own development. Efficient cooling system equipment is a wise choice. Kaideli is willing to combine its own 20 years of experience in R & D, design and production of advanced chiller equipment to provide beverage companies with high-quality, high-value-added products, and use five-star after-sales service to ensure worry-free product use. To guarantee, use Kaydeli!

Recommended news

-

To create "Guangdong-Hong Kong-Macao Greater Bay Area Industrial Refrigeration Hub", Kaydeli uses its heart to create unlimited cold power!

2020-04-09 -

Kaydeli water-cooled screw chiller, energy saving and efficient

2020-04-07 -

1200 kilometers! Kateley's 5A star after-sales service helps Hangzhou customers resume production

2020-03-28 -

To win the "double battle" of epidemic prevention and control and economic development, Kaydeli has been in action!

2020-03-25 -

2019 Shenzhen International Film & Tape Exhibition

2019-11-09