Cooling water system design and installation

The cooling water system is designed in this way, saving electricity and money!

For the cooling water system, it is responsible for cooling the condenser of the refrigeration system. Air-cooled refrigeration uses air cooling to cool the condenser, so no cooling water system is needed, and only the water-cooled chiller has a cooling water system design.

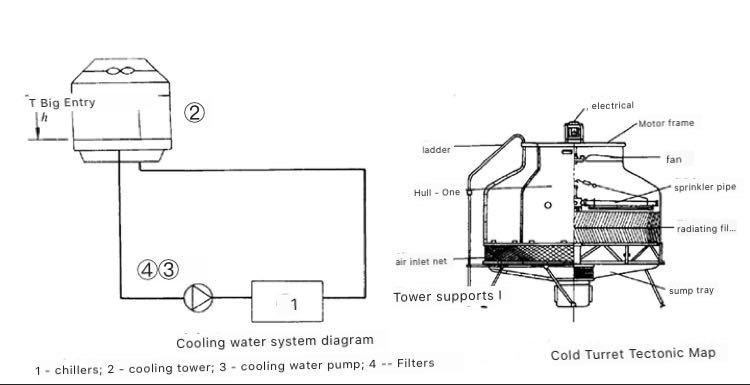

The cooling water system is generally composed of a cooling water tower, a condenser, and a cooling water circulating water pump. Therefore, water pumps and water towers are important parameters that restrict the energy-saving performance of the system. Improper selection will not only waste equipment costs, occupy space, but also affect the cooling effect and even damage the equipment. Then Kedley editor will show you how to design a more efficient cooling water system!

Generally, the outlet temperature of the condenser is above 37 degrees. The high-temperature water is transported into the water tower through the pipeline. The water tower sprays high-temperature water and mixes with the air to evaporate and cool.

So the requirements for the cooling water system are as follows:

Water tower contains water quality treatment device

The quality of the water will affect the efficiency of the water outlet. Because the water contains salt substances, it will be concentrated due to evaporation and block the pipeline. Equipped with a water quality treatment device will improve the quality of the circulating water and avoid pipeline blockage.

The surrounding environment of the water tower

Choose a dry and ventilated environment, and there are no obstacles at the outlet of the fan;

At the same time, consider whether the surrounding environment has noise requirements, and select low-noise or variable-speed water towers;

To prevent the impact of floating water on the surrounding environment, if there are weak and strong equipment around, it should be avoided;

Consider whether there are fire protection requirements.

The water supply of the water tower is moderate

With the operation of the system, the water level in the water tower will slowly decrease, and water replenishment should be timely to avoid the insufficient water level affecting the cooling temperature. The amount of make-up water is generally 1∽3% of the circulating water volume of the cooling tower;

When multiple water towers are connected in parallel, it is necessary to avoid the uneven distribution of the water resistance caused by the pipeline resistance or the overflow of the water in the bottom pool of the cooling tower.

The cooling water pump power is matched with the system

The water pump plays the role of transporting high-temperature water to the water tower and the cooling water to the chiller. Small power will cause the condenser temperature to be high, and high power will increase the cost of the equipment and match the system best.

Easy maintenance and cleaning

As mentioned above, the water quality environment in the water tower, the operation of the motor, and the corrosion of the pipeline will make the entire cold water system become inefficient. Regular maintenance and cleaning will increase the service life of the system.

Selection method of cooling tower:

★ According to the cooling water volume of the chiller and the temperature and temperature difference of the supply and return water, select the appropriate type of water tower. Generally, the chiller equipment will have a standard cooling water volume. According to the product model of the water tower, select the water tower of corresponding specifications. The cooling effect of the water tower is mainly determined by the actual air wet bulb temperature, so it should be calculated based on experience.

★ Simple experience value calculation formula:

Cooling water volume = host cooling capacity (KW) * 1.2 * 1.25 * 861/5000 (m³ / h)

Note: 1.2 is the selection margin, 1.25 is the condenser load factor

For example, a chiller with a cooling capacity of 300KW requires a cooling water volume of about 86m³ / h. According to the cooling water volume, refer to the cooling tower sample to select the appropriate cooling water tower.

Selection method of cooling water pump:

Chillers should choose cooling water pumps based on energy-saving, low noise, less floor space, safety and reliability, low vibration, and easy maintenance. Generally, flow and head are the main performance parameters.

The following is the reference of the resistance loss of the cooling water system, plus the height difference of the cooling water tower to calculate the head of the cooling system.

★ The water resistance of the condenser of the refrigeration unit: generally 5 ~ 7mH2O; (For specific values, please refer to the product sample)

★ Water spray pressure of cooling tower nozzle: generally 2 ~ 3mH2O

★ The height difference of the cooling tower (open cooling tower) from the water tray to the nozzle: generally 2 ~ 3mH2O

★ The resistance of the return water filter is generally 3 ~ 5mH2O;

★ Refrigeration system water pipeline resistance and partial resistance loss: generally 5 ~ 8mH2O;

As can be seen from the above, the cooling water pump head is 17 ~ 26mH2O, generally 21 ~ 25mH2O. Once we have determined the flow rate and head, we can select the model according to the pump manual. Through the design of the entire cooling water system, the best and most energy-efficient system design scheme can be selected to minimize the cost of enterprise equipment.

Recommended news

-

To create "Guangdong-Hong Kong-Macao Greater Bay Area Industrial Refrigeration Hub", Kaydeli uses its heart to create unlimited cold power!

2020-04-09 -

Kaydeli water-cooled screw chiller, energy saving and efficient

2020-04-07 -

1200 kilometers! Kateley's 5A star after-sales service helps Hangzhou customers resume production

2020-03-28 -

To win the "double battle" of epidemic prevention and control and economic development, Kaydeli has been in action!

2020-03-25 -

2019 Shenzhen International Film & Tape Exhibition

2019-11-09